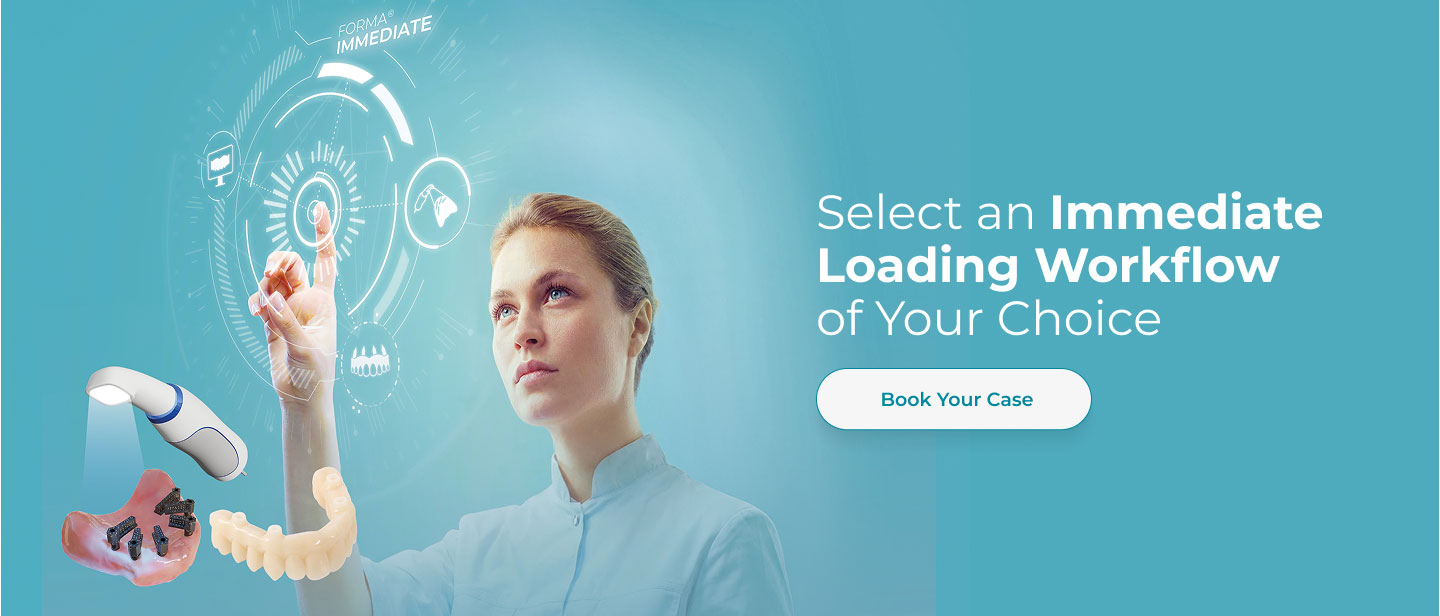

The All-on-EASY™ method: Immediate loading made predictable through digital simplicity.

All-on-EASY™ is a structured, digitally driven workflow that simplifies the execution of immediate loading without compromising clinical principles. It reduces procedural complexity by standardizing planning, prosthetic preparation and lab–clinic coordination around a predictable protocol.

All-on-EASY™ does not make surgery easier, it makes immediate loading more controllable, repeatable, and reachable for GPs.

Digital Planning First

Speed without Stress

Immediate Confidence

Reachable for All Dentists –

GPs and Implantologists

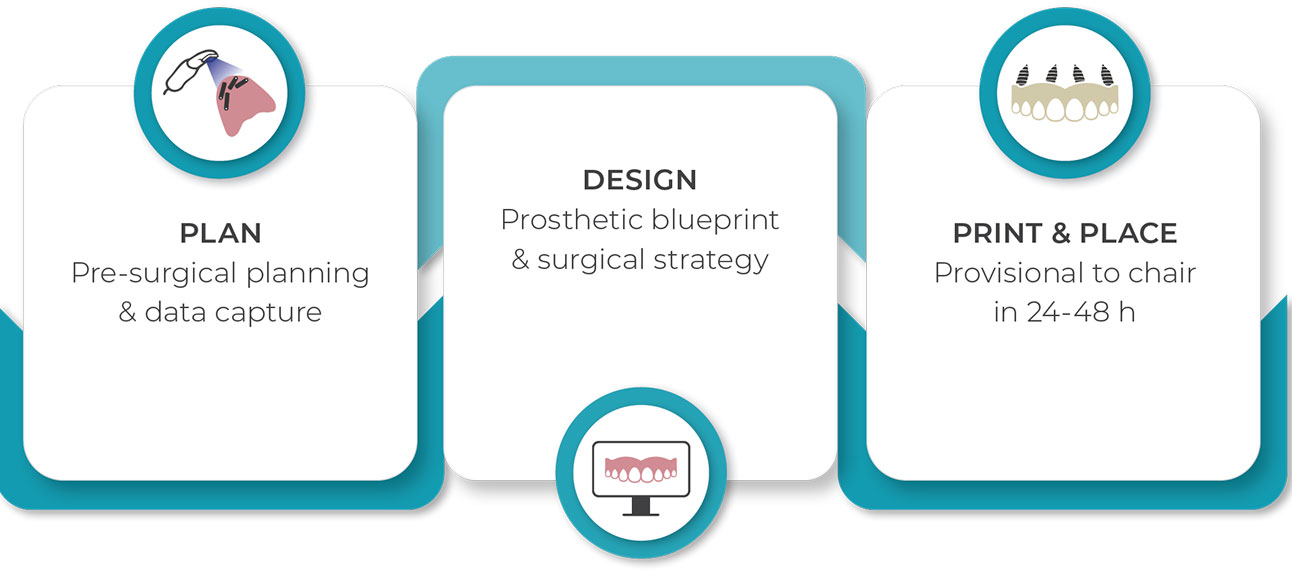

All-on-EASY™ is our mindset: make immediate loading predictable through digital simplicity. Forma® Immediate is the workflow that turns that promise into a clear, step-by-step Plan–Design–Print & Place pathway.

Forma® Immediate Redefines Immediate Loading in Implantology-

Forma® Immediate is a dentist-friendly, step-by-step, flexible digital workflow for immediate loading in single implants, bridges, and full-arch All-on-X cases. It follows one consistent pathway of Plan, Design, and Print and Place, making even complex treatments easier to manage.

ALL-DIGITAL WORKFLOW:

A unified digital pathway that connects scanning, planning, design, and fabrication, keeping every clinical step connected and predictable, from start to provisionalisation.

ACCURACY :

High-quality data acquisition, validated extensive pre-surgical design plans and collaborative dentist-lab communication reduce errors and improve fit. Presenting the Direct-to-MUA immediate loading bridge for All-on-X cases that uses the special flat-head cone-shaped screws. It removes Ti-bases, cementation needs for a more stable passive fit.

SPEED:

Designed for speed and reliability. With design services as fast as 60 minutes, accelerated turnaround becomes achievable. Efficient data capture, rapid design support, and real-time chat functions make it ideal for same-day and immediate loading cases.

INTEGRATIVE SMILE DESIGN APPROACH:

Uses 3D CBCT, X-rays, facial scans, digital occlusion, jaw-movement tracking and 2D photos to align aesthetic planning with functional requirements for lifelike immediate loading implant provisional.

CONFIDENT FULLY GUIDED SURGERY:

Digitally planned implant positioning supported by CAD/CAM resin or metal surgical guides or stackable guides for All-on-EASY™ placement, surgical precision, and less intraoperative surprises.

REAL-TIME COMMUNICATION WITH PERSONAL DASHBOARDS:

Centralised order platform that connects clinics and labs for clear data exchange, faster decisions, and full case visibility, supporting the teamwork essential in implant dentistry and helping dental teams work with confidence.

How Does Forma® Immediate Work?

Step 1: Plan

Dentists begin by submitting IOS scans, bite registration data, CBCT data, with optional facial scans or jaw-tracking when available. These inputs form the basis for assessing anatomy, prosthetic space, and restorative needs before any surgical decisions are made. From there, the lab delivers a validated virtual case plan, a surgical guide design, and tentative immediate loading bridge design.

Step 2: Design

Dentist uploads the final post-surgical implant scans using scan bodies, horizontal scan flags, with or without IPG/Intra-oral photogrammetry or extra-oral photogrammetry as indicated, ensuring the design stage reflects accurate implant positions, soft-tissue contours and restorative space. Using these updated records, the lab creates the final design CAD for the immediate loading bridge. All designs are reviewed in real time through the order platform, where feedback, comments and approvals are captured to ensure precision and a seamless transition to production.

DESS® Dental Scan Abutment:

is designed for accuracy and precision in single implant cases; needs no hex driver and removes distortion in scans.

Apollo® SmartFlags:

offers unique-fit horizontal scan bodies for different MUA platforms offerinng highest accuracy.

ScanLadder:

offers a randomized surface that horizontal scan bodies creating unique, trackable reference points for IOS.

CAPS:

Complete Arch Pillar System ensure accurate full-arch scans together with digital bite registrations for edentulous arches.

TruAbutment iOConnect:

offers fast scan startgeies together with accurate soft tissue scanning.

Eletra HAT Scanbody:

delivers precise, fast, comfortable scanning with automatic calibration and versatile workflows for efficient modern digital dentistry.

Shining 3D IPG HACS kit:

This High-Accuracy-Coded Scanboby kit offers 2-in-1: IOS and IPG (intra-oral phtogrammetry) on one device.

Imetric 4D ICam photogrammetry:

Extra-oral photogrammetry offering 3D implant scans.

Step 3: Print and Place

Depending on your workflow, you can choose how to complete the final step. You may opt for Design-Only, where we create the digital design and you 3D-print the provisional in your clinic. Alternatively, select Design-and-Print, where our lab designs and prints the temporary bridge and delivers it to you within 24-48 hours. For clinicians seeking full surgical control with a combination of digital and analogue, a third option includes the Stackable Guides, enabling fully guided implant placement and chairside conversion of the guide into a temporary bridge.

6 Features of Predictable Immediacy and Why It’s Beneficial

Digital Planning First

- Proactive co-planning (patient-dentist-lab) locks in case predictability and de-risks surgery.

- Virtual implant case plan + default surgical guides for every case.

- Clear approvals on a digital order platform, so no last-minute surprises, lengthy lab sheets, and back-and-forth.

Speed without Stress

- Chairside or lab-side temporary implant crown or implant bridge in 24-48 hours depending on indication and logistics.

- Faster approvals via mandatory, stepwise intake = fewer reworks.

Immediate Confidence with Passive Fit High Accuracy

- IPG (intra-oral photogrammetry) or

brand‑specific horizontal scan flags, use

your favourite implant scan kit to deliver

verifiable, micron‑level precision. - Passive fits support prosthetic hygiene and soft‑tissue management.

- Accuracy you can count on → reduces chairside adjustments later.

Flexibility First, Not Product Pushed

- Design-Only, Design-and-Print, or Stackable Guides, right‑size the service to your clinic.

- Open source compatibility: bring your own IOS, printers, and resins; edit designs pre‑surgery.

- No mandatory purchases + clinical‑driven customisation, guided by human experts, not bots

Direct-to-MUA, No Ti-base

- No cementation, cleaner restorations.

- Lean inventory, simpler chairside for

All‑on‑X provisionals. - Hygiene-first prosthetics without extra interfaces.

End-to-End Support to GPs and Impantologists

- Mandatory, sequential intake on our digital order platform → green‑lights cases faster.

- Expert technicians & designers in real‑time chat; data retained from immediate to final.

- One partner, many hats (lab + distributor) last‑minute parts, education, and fair pricing. lengthy lab sheets, and back‑and‑forth

Why Now Is the Best Time to Introduce Immediacy in Your Implant Practice?

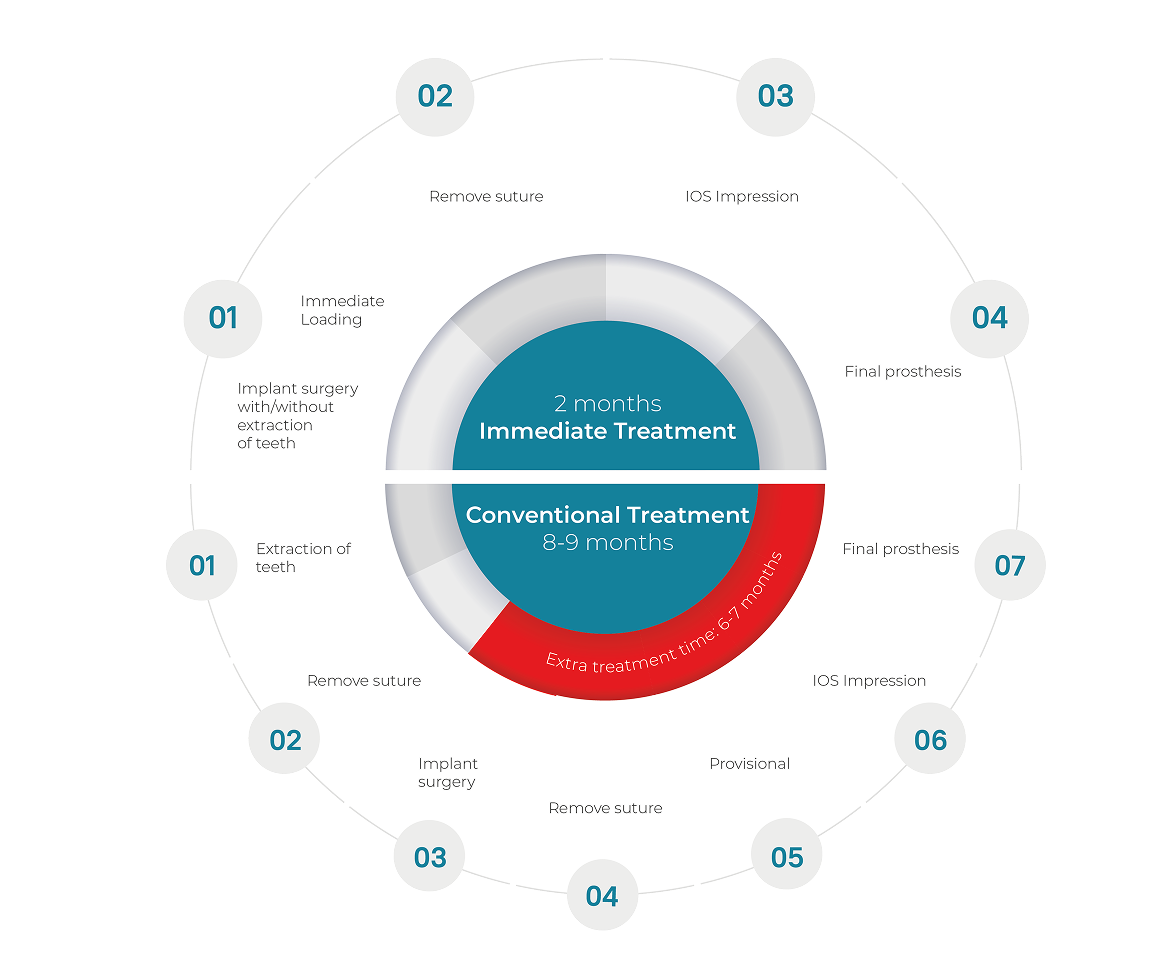

A decade ago, delivering an immediate temporary crown often meant double the investment and 5–8 hours of planning and preparation.

Today, All-on-EASY™ brings predictability through digital simplicity, and Forma® Immediate turns that into a clear Plan–Design–Print & Place workflow. Digital pathways have been shown to shorten fabrication time and improve provisional fit compared with conventional workflows, helping teams move from lengthy back-and-forth to faster, more reliable execution.

Patients have also changed.

Many no longer accept months without teeth; they value function and aesthetics sooner, and studies on immediate loading report high patient-rated importance and improved satisfaction, especially linked to receiving a fixed solution quickly and restoring comfort and confidence earlier.

In other words, immediacy isn’t a “special case” anymore.

With the right digital protocol, it’s becoming a standard expectation, and Forma® Immediate is built to make that expectation more controllable and repeatable for everyday practice.

Conclusion: Today’s Immediate is Tomorrow’s Prototype

Immediate loading in implantology is just the first step towards a successful implant restoration. All case data is retained, and this immediate temporary bridge acts like your Try-in bridge after the osseointegration phase. We use it as a prototype for the final implant prosthesis. Thus, the definitive prosthesis lands faster now with fewer adjustments.

FAQs

-

What is the concept of immediate loading?

Immediate loading refers to the concept of placing a temporary implant crown or bridge within 24-72 hours of the implant surgery. It can be combined with or without immediate implant surgery. It helps maintain the peri-implant soft-tissue integrity throughout the osseointegration phase. Ideal for patient satisfaction- instead of waiting months for healing, patients leave the clinic with a functional, aesthetic provisional.

-

How long will a temporary dental bridge last?

Our immediate loading temporary bridge is designed to last several weeks to a few months, depending on the case. Its purpose is to support healing, maintain function and aesthetics, and guide soft-tissue shaping until the final prosthesis is delivered.

We take precautions to ensure longevity – accurate printing of the screw seat, right choice of highly-filled 3D printing resins, specialized flathead, reverse-tapered direct-to-MUA prosthetic screws and chairside use instructions. -

When to do immediate loading?

Immediate loading is appropriate when:

- Adequate bone quality and quantity (typically D1–D2).

- Achievable primary stability of at least 30–35 Ncm insertion torque.

- High Implant Stability Quotient (ISQ) — generally ≥70 for single implants, and ≥60–65 when implants are splinted.

- Occlusion can be controlled

- Digital workflows like Forma® Immediate allow clear communication and design reviews.

-

What are the best chairside tips for immediate loading?

- Occlusion overview: avoid heavy centric contacts and eliminate lateral guidance.

- Confirm fit and passivity before tightening screws.

- Use the recommended torque value from the implant brand; usually recommended ≤ 15Ncm.

- Ensure the provision is smooth, polished, and free of sharp edges.

- Verify adequate clearance to prevent fracture or overloading.