Choose quality impression materials, rigid trays and package them securely.

BOOK A COLLECTION

SCD offer a free of charge courier collection and delivery service for our customers across Ireland and the United Kingdom.

This supports the transport of impressions and completed cases to and from our 3 locations in Dungannon, Dundalk and Leeds.

Please complete this online form to arrange for a collection at your practice.

Each set of impressions must be securely packaged within a case box and our address should be visible on the outside. We recommend that you use an SCD satchel and this will help ensure that the case is delivered successfully to us.

Other notes:

- If you are booking a collection before 9:30am we will endeavour to collect it the same day. If your collection is booked after 9:30am in most instances it will be collected the next business day.

- We would encourage you to book your collection 1 working day in advance to avoid any delays

- Please ensure that you have calculated sufficient turnaround time prior to booking your patient for their fit appointment. Turnaround is calculated from the date that SCD receives your case not the date that it is collected by the courier.

FREE POSTAL LABELS

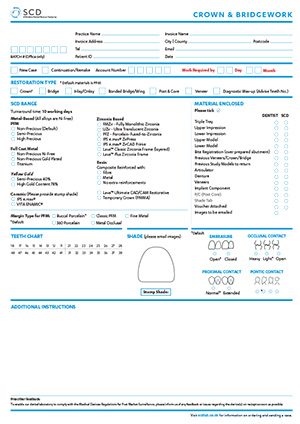

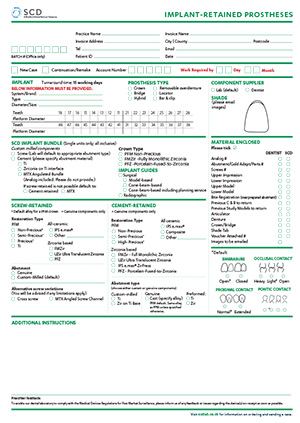

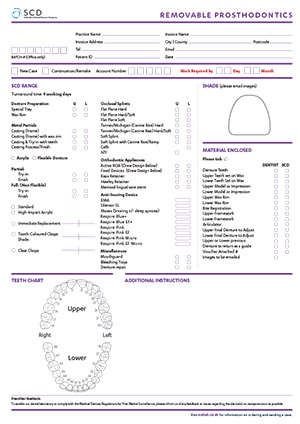

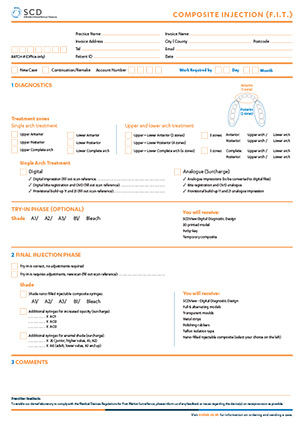

LABORATORY FORMS

Impression Taking Advice:

The art and science of taking impressions or scans, with their multiple interrelated steps, has many areas where potential discrepancies may be introduced.

A lack of fit most often results from inaccuracies in the impression, some of which may be difficult to detect chairside at the time of record taking.

Use impression materials with excellent tear resistance, suitable viscosities and shelf lives in order to produce optimal outcomes. For example, Polyvinyl siloxane (PVS).

Features of a Good Impression:

- Rigid sturdy impression tray.

- Tray adhesive applied thoroughly (when required).

- Uniform homogenous mix.

- Strong bond between impression material and tray.

- No tooth contact with the tray.

- String bond between heavy-body and light-body materials.

- No voids or pulls on margin, axial walls or occlusal table.

- All margins and axial walls are in light-body material – no ‘burn-through” of the heavy-body material.

- All margins show clear detail with no tears, voids or rough surfaces.